Spring balancer technology has carved out a significant niche in industries that require precision, efficiency, and enhanced ergonomics. These devices are engineered to hold and support hand-operated tools, effectively reducing the physical strain on operators and enhancing productivity. The core functionality of spring balancers lies in their ability to counterbalance the weight of the tool, thereby providing nearly weightless operational handling. This technology is especially crucial in environments where repetitive tasks could lead to operator fatigue or injury.

The flexibility of spring balancers is a standout feature. They cater to a diverse range of applications, serving sectors such as automotive assembly, electronics, and general manufacturing. This adaptability is made possible by the devices' ability to smoothly retract a tool to its designated position once the operator releases it, ensuring that workspaces are kept organized and free from clutter. Moreover, the adjustable tension of spring balancers allows them to accommodate tools of varying weights and sizes, from heavy-duty wrenches to delicate soldering irons, without compromising on safety or efficiency.

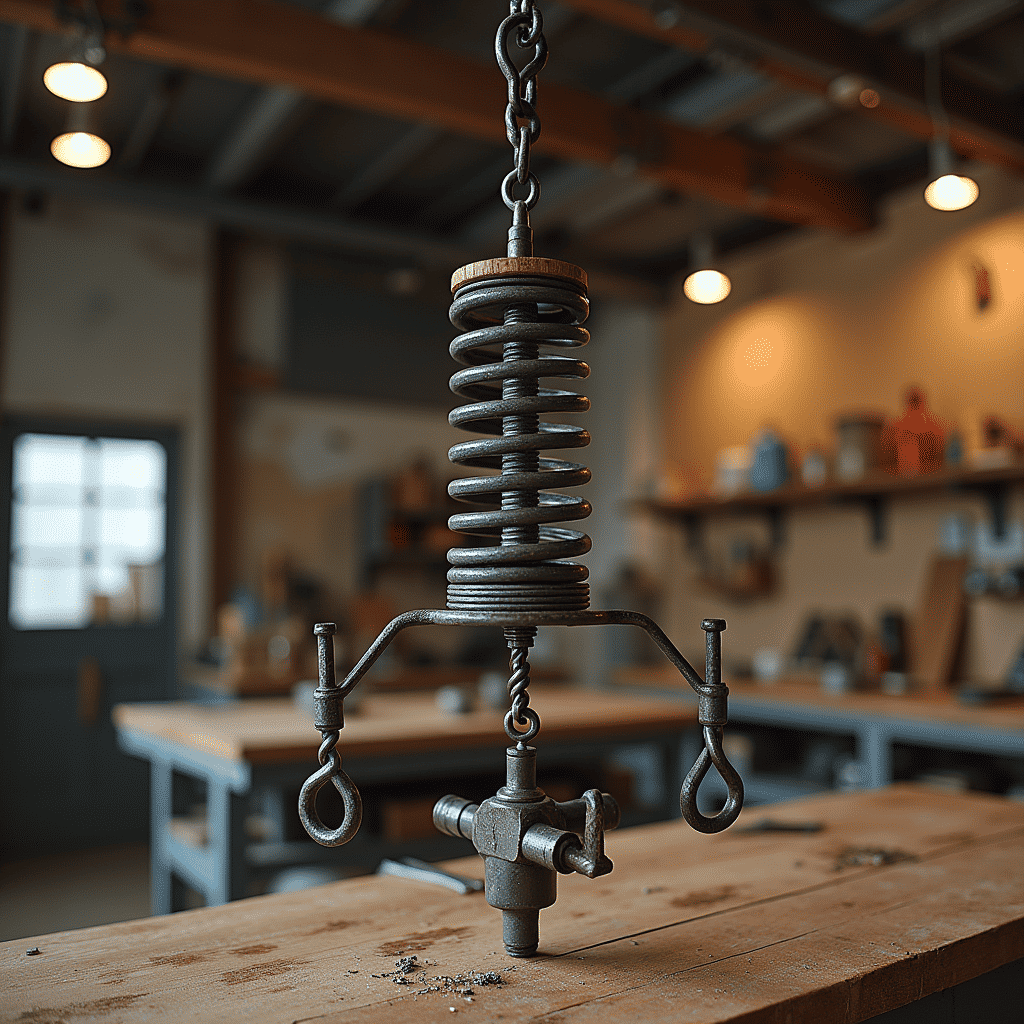

What sets modern spring balancers apart is their design innovation. Today’s models come equipped with enhanced safety features like anti-drop functions and automatic tool retrieval, minimizing the risk of accidents. Furthermore, the use of high-quality materials in their construction ensures durability and a long service life even under the most demanding conditions. These enhancements not only protect operators and tools but also contribute positively to an organization's bottom line by reducing downtime and maintenance costs.

The ergonomic benefits of spring balancer technology are also significant. By suspending tools in a weightless state, operators enjoy reduced strain on their muscles and joints, lowering the likelihood of repetitive strain injuries. This ergonomic advantage translates into better job satisfaction and increased efficiency, as workers can complete tasks with greater ease and precision. Additionally, the consistent support provided by spring balancers helps ensure uniform application of force, improving the quality and consistency of the work produced.

In conclusion, the innovative design and functionality of spring balancers make them indispensable assets in numerous industrial applications. By alleviating the physical and organizational demands of tool handling, they contribute to safer work environments and more efficient workflows. As industries evolve and the emphasis on employee wellness and productivity grows, the role of spring balancer technology is set to become increasingly prominent, ensuring smooth and adaptable movements across a wide array of applications.