In the fast-paced world of industrial operations, the need for balancing efficiency with safety is more critical than ever. With industries continually pushing the boundaries for improved productivity, the innovations in industrial balancing equipment have emerged as pivotal advancements. These innovations not only streamline operations but also enhance safety measures, ensuring a seamless and secure working environment.

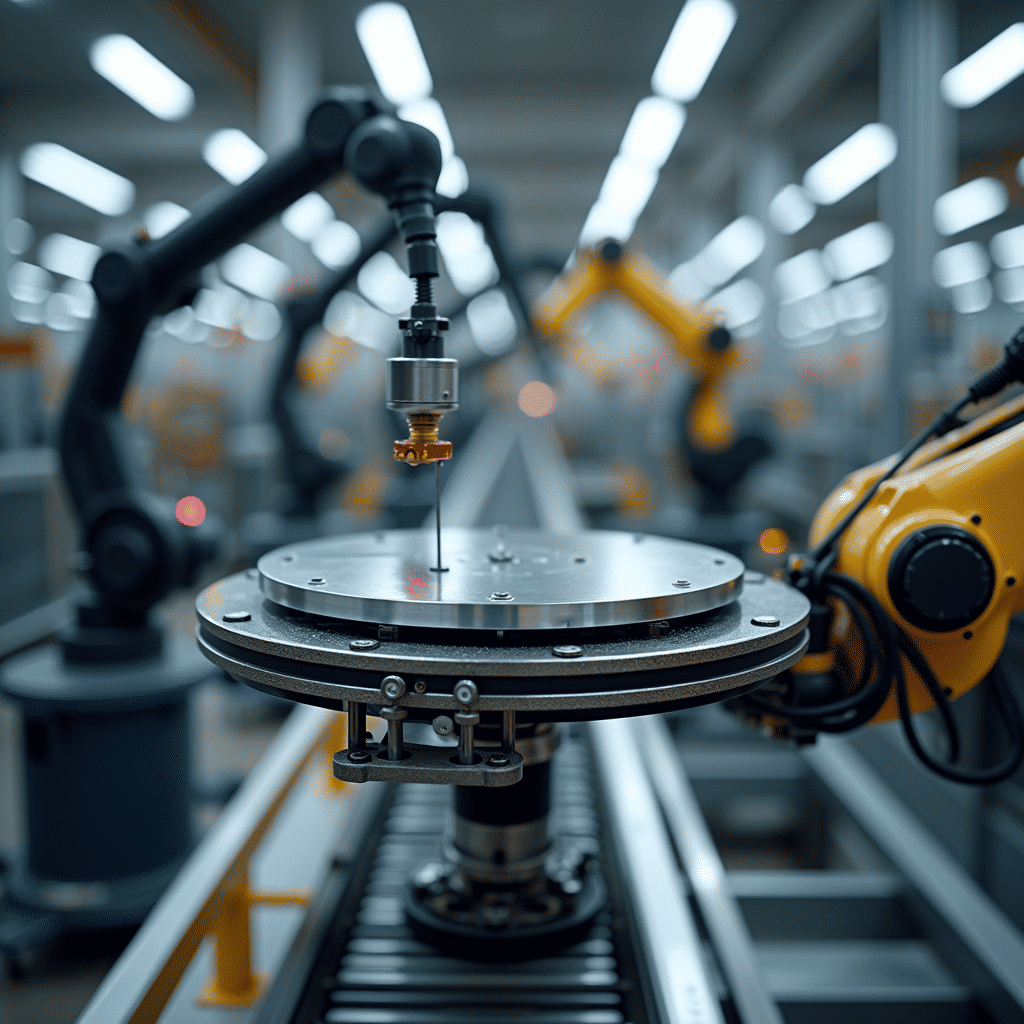

At the core of these innovations is the integration of cutting-edge technology designed to address the challenges faced by modern industries. One significant advancement is the development of automated balancing systems. These systems employ advanced sensors and real-time monitoring to detect and correct imbalances in machinery without the need for manual intervention. This automation dramatically reduces downtime, allowing operations to continue smoothly and without interruption.

In addition to automation, modern industrial balancers are now infused with intelligent software that provides predictive maintenance insights. By analyzing data patterns and machinery performance, these advanced systems can anticipate maintenance needs before issues arise. This proactive approach not only prevents potential breakdowns but also extends the lifespan of equipment, leading to cost savings and increased operational efficiency.

Safety is a paramount concern in any industrial setting, and the latest balancer innovations do not disappoint in this regard. Enhanced safety features, such as emergency stop functionalities and fail-safe mechanisms, are now standard. These features are designed to immediately halt operations if any potential hazards are detected, thereby protecting not only the equipment but also the personnel operating them.

Moreover, ergonomic designs in modern industrial balancers have revolutionized the way operators interact with machinery. Features such as adjustable components and user-friendly interfaces reduce physical strain on workers, fostering a more comfortable and productive work environment. By prioritizing operator well-being, companies can reduce the incidence of work-related injuries, which directly contributes to higher productivity and job satisfaction.

The push towards eco-friendly solutions is another noteworthy trend in the world of industrial balancing. The latest models prioritize energy efficiency and sustainability, utilizing materials and technologies that minimize environmental impact. These innovations not only align with global sustainability goals but also provide companies with significant savings in energy costs.

Industries as varied as automotive, aerospace, and heavy machinery manufacturing are beginning to leverage these innovations to elevate their operational standards. By adopting the latest in industrial balancing technology, they set themselves apart as leaders in both performance and safety. As these trends continue to evolve, it is clear that the future of industrial operations will be defined by a harmonious balance between technological advancement and human-centric design.

In conclusion, the innovations in industrial balancers are setting new benchmarks for productivity and safety. By integrating advanced automation, intelligent software, robust safety features, ergonomic designs, and sustainable practices, these innovations empower industries to operate at optimal levels. As technology continues to advance, the possibilities for further improvements in industrial balancing are limitless, promising an era of unprecedented efficiency and safety in industrial operations worldwide.